Recently viewed

Vesda FAQ's

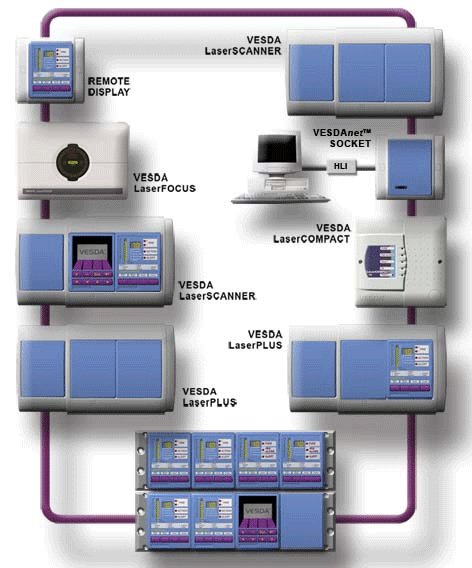

A VESDA system constantly samples the air through a network of pipes and analyses it for the smallest traces of smoke, providing advanced warning long before conventional detectors activate.

Traditional smoke detectors respond once smoke has already reached the sensor. VESDA, however, actively draws in air and analyses it, making it far more sensitive and capable of giving earlier alerts.

VESDA systems are designed with maintenance in mind. While they do require periodic filter changes and system checks, servicing is straightforward for trained engineers.

The initial investment is higher than standard detectors, but the early warning benefits, reliability, and reduced downtime often make VESDA more cost-effective in high-value or mission-critical environments.

VESDA detectors integrate with conventional or addressable fire alarm panels via relay outputs or direct communications modules, allowing alarms and fault signals to be reported instantly.

Typically, filters last 2–4 years, depending on the environment. In dustier conditions, they may need replacing sooner to keep the system working effectively.

Test points are positioned on the sampling pipe network, usually at accessible locations, to allow engineers to introduce smoke or test gas during routine maintenance.

VESDA systems use multiple alarm stages, often including:

Alert – very early smoke detection

Action – smoke levels increasing, investigation required

Fire 1 – significant smoke detected

Fire 2 – high concentration, immediate response needed

VESDA is typically required in high-risk or sensitive environments such as data centres, cleanrooms, cold storage, airports, and heritage buildings where early detection is vital.

Still Have Questions?

If we still haven't answered your question, you can contact us below and we will get back to you as soon as possible.